Historically, EPSYL’s core business has been the modelling and simulation of physical phenomena. Initially focused on thermal engineering, EPSYL has extended its scope of expertise to other types of physics to better represent the reality of the phenomena studied.

EPSYL is qualified to offer studies in mechanics (design and calculations), fluidics (single or multiphase, liquid or gas), process engineering and finally thermal engineering.

EPSYL stands out for its mastery in the coupling of thermal and fluidic, thermal and mechanical, and thermal and electromagnetic physics. EPSYL also intervenes in more complex cases involving violent phenomena or those considered "rapid dynamic" (fire, explosion).

Even if its core activity involves modelling and simulation, EPSYL has developed several experimental platforms to carry out validation tests or to create equipment in order to perform tests. The measurements taken make it possible to validate or correct the models, thus closing the loop.

EPSYL is agnostic when it comes to the simulation software used. While trying to streamline the number and cost of software, EPSYL strives to adapt to the preferences of its customers by offering either well-known digital tools from large publishers or less well-known "open-source" type tools from large international laboratories.

Some Examples of our Activities:

Safety by Digital

- The field of energy storage and more particularly batteries and the associated thermal issues: modelling and simulation of thermal, fluidic and mechanical phenomena of a battery in normal operation or in critical phases ("thermal runaway"),

- The field of hydrogen and fuel cells: modelling and simulation of hydrogen production, storage and distribution systems; modelling and simulation of explosions,

- The field of nuclear waste storage: modelling and simulation of the thermal behaviour of a radioactive waste package.

Ageing by Digital

- The field of complex assemblies and the modelling of their properties over time: evolution of solders or welds in the field of electronic boards, heat exchangers or systems subject to high constraints (ITER).

Thermal Management by Digital

- Cooling of electrical or electronic systems,

- Thermal optimization of space objects,

- Heat networks.

Fluidic Management by Digital

- Calculating size of fluid networks,

- Aircraft icing,

- Air ventilation of industrial plants.

Process by Digital

- P&ID, PFD calculations

- Calculating installation dimensions,

- Process optimization.

Software

Mechanical Design

- Solid Works

- Catia

- Autocad

3D Modelling

- NX Advanced Thermal

- FloTherm

- Ansys Fluent and Mechanical

- NX Nastran

- Solid Works

- Star CCM+

- LS-DYNA, RADIOS

1D modelling or system approach

- Flow Master

- OpenModelica

- Dymola

- Amesim

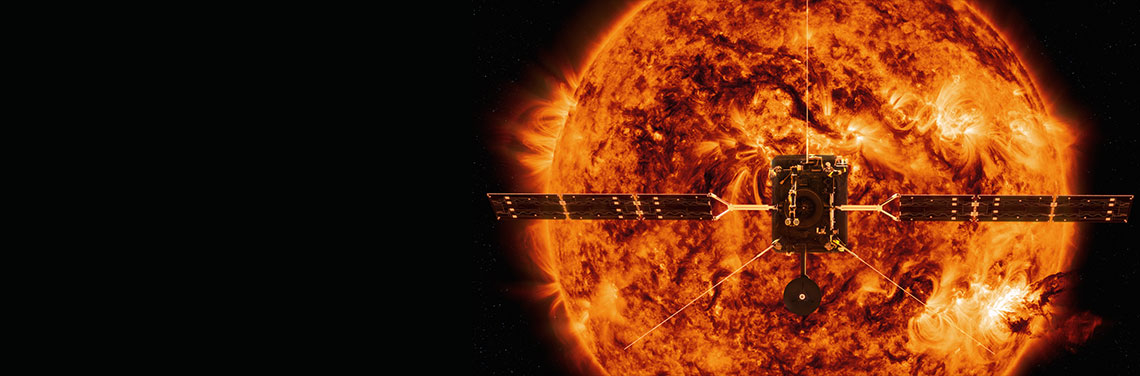

Example of a “Physics” Project

As part of the Solar Orbiter mission, EPSYL carried out several types of thermal engineering studies on certain on-board instruments:

Definition of Thermal Control

- Identified the most constraining thermal environments for the on-board instruments via modelling and simulation,

- Sized and validated the on-board thermal control system.

Test Campaigns

- Defined test and validation protocols,

- Assembled thermal management components (heaters, thermocouples, MLI, etc.) for flight and testing,

- Followed up on thermal campaigns in 3×8.

Correlation and Delivery of the Thermal Model of the Instrument Analysed

- Compared and adjusted the model to test measurements,

- Built and delivered the thermal scale model for satellite analyses

As part of the Solar Orbiter mission, EPSYL carried out several types of thermal engineering studies on certain on-board instruments:

Definition of Thermal Control

- Identified the most constraining thermal environments for the on-board instruments via modelling and simulation,

- Sized and validated the on-board thermal control system.

Test Campaigns

- Defined test and validation protocols,

- Assembled thermal management components (heaters, thermocouples, MLI, etc.) for flight and testing,

- Followed up on thermal campaigns in 3×8.

Correlation and Delivery of the Thermal Model of the Instrument Analysed

- Compared and adjusted the model to test measurements,

- Built and delivered the thermal scale model for satellite analyses