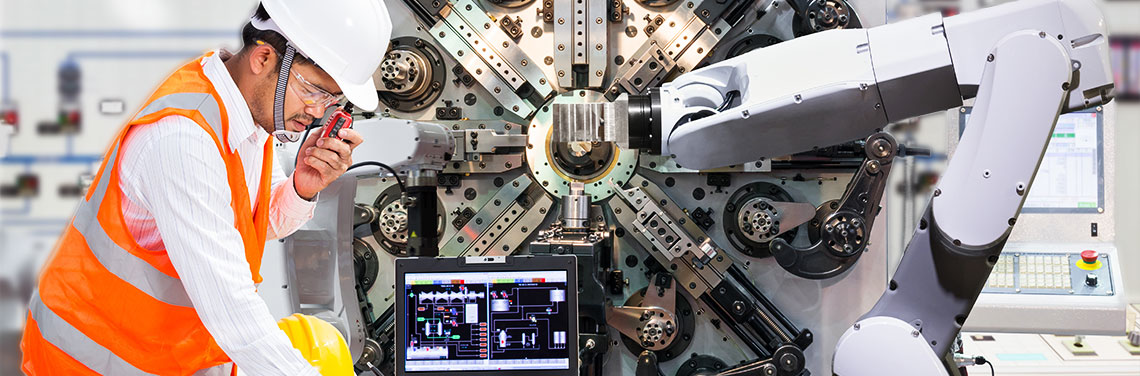

EPSYL’s operations are dedicated to systems and follow diverse approaches:

- A "test bench" approach: Designing, integrating and testing scientific equipment or test benches. The notion of "system" is linked to the multi-technical aspect of the studies carried out.

- A "modelling" approach: Optimizing systems using simplified models (0D, 1D) to determine their operating or technical-economic optimizations. This approach is complementary to the traditional 3D modelling and simulation approach.

Both approaches draw from each other.

“Test Bench” Approach

EPSYL has several technological platforms to undertake so-called design/implementation projects. Its teams have developed multi-technical know-how (from mechanics to industrial computing) and system optimization expertise in order to create scientific equipment or test benches. Whereas EPSYL's competitors might consider such diverse work impossible, this is our core target.

To complement modelling and simulation, it is essential to also undertake activities related to testing, as these two activities are complementary:

- Tests are used to validate models

- Models make it possible to multiply experiments or to digitally carry out inaccessible experiments

EPSYL is not alone in carrying out this type of project and in some cases joins forces with other subsidiaries of the ALCEN group or other companies to complement its know-how or resources.

EPSYL is a service company that meets the specifications of its clients. At the same time, EPSYL develops its own range of products, always with a focus on innovation in thermal, fluidics or software.

Diphasik - Cooling technology resulting from a partnership with ATMOSTAT

The mechanically pumped two-phase fluid loop is an efficient, innovative and industrial solution that uses latent heat of evaporation as a means of heat transfer operating at a very low thermal gradient.

Our solution is particularly suited to the problems of cooling high-power electronics (space, rail… ). The densification of electronic components and the limited yields imply having to solve the problem of heat dissipation at high power density.

Characteristics:

- Closed loop, sealed, pressurized, loaded with two-phase fluid.

- High compactness of heat transfer.

- High density of removable power.

- Fluids suitable for holding wide temperature ranges.

Applications:

- Thermal management of high density power electronics and operating in a highly constrained environment.

- Thermal management of components based on large gap semiconductor materials such as Silicon Carbide (SiC) or Gallium Nitride (GaN).

- A solution for on-board and/or confined systems such as aircraft, "more electric" vehicles or mobile objects, renewable energies, etc.

DEsProTherm - Equipment for Measuring Thermal Properties

Thermal capacity, effusivity and conductivity of materials (ceramics, composites, etc.)

EPSYL markets equipment for estimating thermal properties based on the hot plane method and offers custom measurement cells to best integrate the specifics of the products.

The hot plane method deployed in the DEsProTherm device is conventional and consists of measuring temperatures on the front and rear of the sample after thermal excitation. The temperatures measured are then used to estimate some of its thermal properties. The innovation of EPSYL lies in the processing of data from thermal excitation which allows us to go back to the desired physico-chemical characteristics. This data processing is the result of several years of R&D in partnership with the CNRS in the field of thermal engineering. This intuitive and user-friendly software uses multiple calculation algorithms to guarantee reliability of the results.

Easy to use, DEsProTherm integrates an "Electronic module - Power supply - Probes" unit for thermal excitation and acquisition.

The sample is placed on an instrumented resistive circuit and the temperatures are measured by thermocouples. The measurement is fast, non-destructive, and requires only the positioning of the sample.

DEsProTherm is suitable for a wide range of materials: conductors, insulators, metals, ceramics, minerals, fabrics, etc.

It offers a measurement range from ambient to almost 500 °C.

The device is adaptable to your needs (ranges, measurement temperatures, probes, etc.) and transferable to an industrial environment (control on a production line, etc.).

Applications

- Building,

- Automobile,

- Insulation materials, glazing,

- Engineering,

- Metals, plastics, fabrics, ceramics, wood,

- Aerospace,

- Composite materials,

- Metrology

- Sport.

Infrared thermography - SAFIR technology (Soft Analysis For InfraRed)

EPSYL is involved in projects for the design and production of CND Thermal equipment according to the specifications desired by its customers. The © EPSYL-SAFIR data processing and analysis software implemented in this equipment is developed by EPSYL teams.

Applications

- Thermal diffusivity measurement

- Estimation of variations in properties (porosity, thickness, density ...)

- Detection of delamination, inclusions, cracks, welding faults ...

- Quantification of impacts

- Ageing

- Analysis of thermal phenomena (estimation of exchange coefficient from temperature field ...)

- Monitoring, diagnosis, (passive IR thermography)

Fields

- Building: insulation materials, glazing

- Engineering: metals, plastics, fabrics, ceramics, textiles

- Aeronautics: composite materials

- Spatial

- Agrifood, livestock